- Page

- Manual AK I

Manual AK I

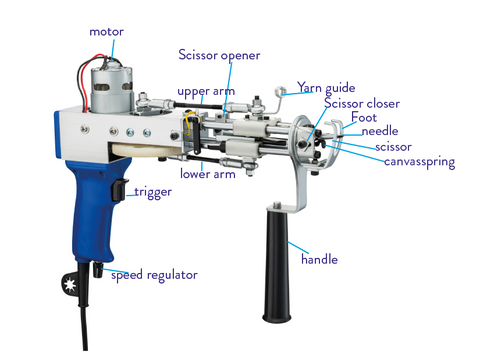

Understanding Your Tufting Machine

AK-I Machine Features

Your AK-I machine comes with an AC/DC adapter, capable of handling up to 240 volts AC. This adapter efficiently transforms AC power to the 30 volts DC required for the tufting gun operation. Its plug is EU standard, but it's compatible with any plug or travel adapter. Here are its specifications:

- Adjustable pile height (7-18mm)

- Speed Range: 5.45 stitches/sec

- Weight: 1.4 kg

- Universal Voltage: 100 - 240 V , 50 - 60 Hz

How to Adjust the Pile Height

Starting from the machine's default settings, follow these steps to set the AK-I to the max pile height:

- Shorten the upper arm to 53 mm.

- Keep the lower arm at its original length, hence, the scissor opener's position remains unchanged.

- Align the foot with the bottom of the needle hole. Adjust it to about 31 mm, the lowest possible.

- Adjust the canvasspring so that it protrudes around 6 mm from the foot. Loosen the bolt, tap it down, and then secure it at 6 mm.

- Finally, adjust the point where the scissor closes. Loosen the screw on the scissor closer, move the wheel to where the scissor opens fully, then push the scissor closer in until the scissors start to close. Secure it at this point.

Finetuning Your Machine

Post-adjustment, your machine's scissors might require some fine-tuning to ensure precise cutting. You can learn more about it in these video guides:

Scissors Closing

Scissors Opening

Modifying the Needle Eye Size

Troubleshooting Your Machine

Performing a Running Check

Always perform a running check after any modifications to the pile height or scissors. If the scissors and needle distance is too large in a uniform height, decrease it by placing a piece of paper under the scissors or manually bending the scissors slightly.

Realigning the Motor and Gear

If the motor gets dislocated, realign it by ensuring the motor wheel correctly touches the white gear wheel. Loosen the four screws holding the motor, position it correctly, and retighten the screws. Watch this video guide for more details:

Maintaining Your Machine

Proper maintenance ensures your machine's longevity and optimal performance. Here are some tips:

- Add a drop of color and odorless lubricating oil to each linear bearing weekly. For longer tufting sessions, oil more frequently.

- Monthly, add oil to the scissor joint and other moving metal parts.

- Regularly clean loose yarn strands and dust from moving parts using a brush or compressed air.

- Always store the machine upright, not resting on the side with the main power switch.

If you face any issues, email info@tuftingshop.com or visit our tufting wiki for common problem solutions.

Restoring Factory Settings

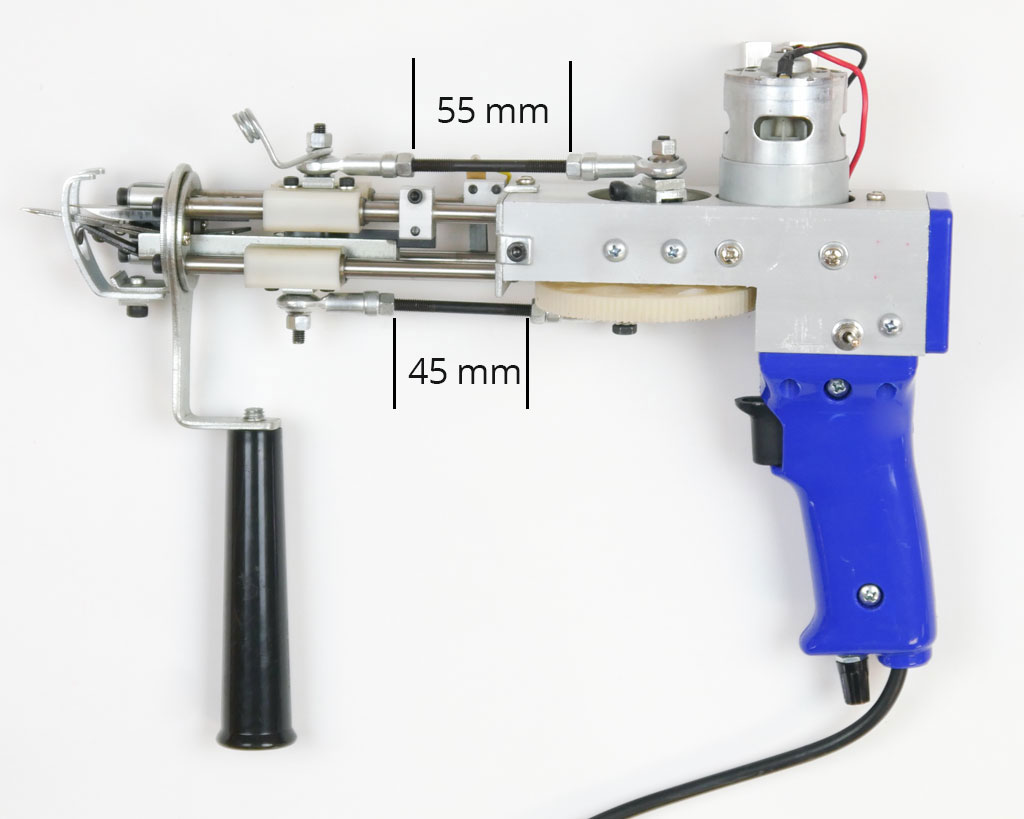

Keeping the machine parts in harmony is crucial for optimal operation. Any changes to the machine settings can misalign them, causing malfunction. Refer to the image below for the factory setting of the arms, and follow the above instructions for other settings.